Wet Ball Mill Calculation

Ball Mill Design/Power Calculation 911Metallurgist

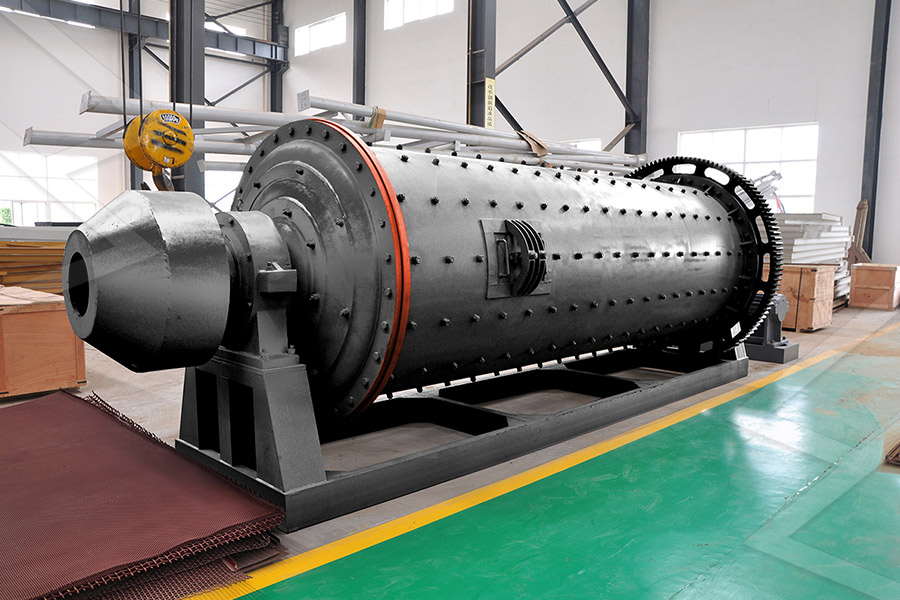

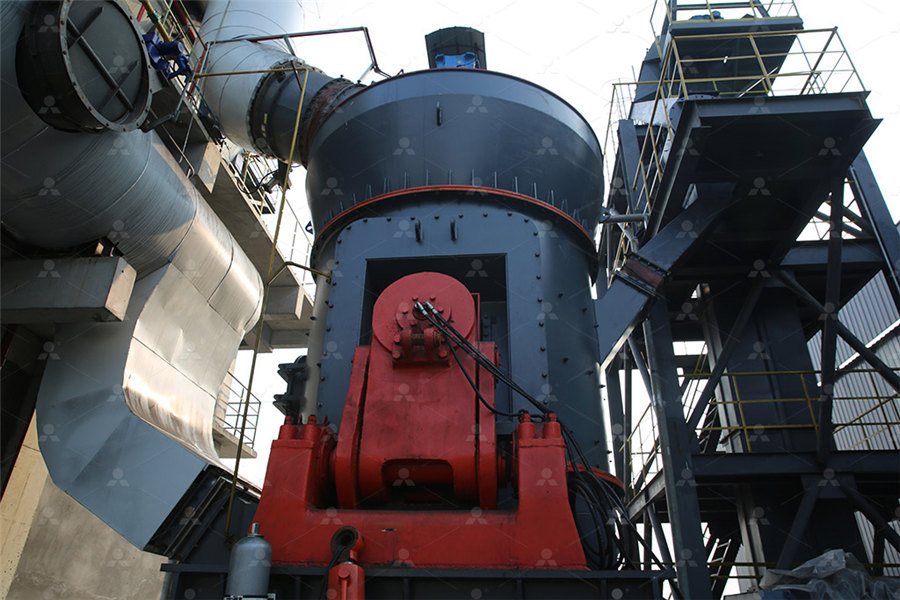

2015年6月19日 Ball Mill Power Calculation Example #1 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% Pilot Plant Design Pilot plant programs provide critical testing and design data Pilot Plant Design2019年8月30日 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting There are many Ball Mill Parameter Selection Calculation JXSC2021年6月24日 The tower mill calculation is based on the ball mill design sheet, but is simplified in that the mill design section is omitted A simple tower mill factor of 70% allows theGrinding Mill Computer Model AusIMM2023年2月11日 One tool used includes a volumebased residence time ball mill model to constrain simulations and prevent ‘overfilling’ and a loss of grinding performance at high Digital Solutions to Evaluate Ball Mill Circuit 2001年10月1日 Bond's method (Bond 1952, 1961), which is a powerbased method, is still the principal way for bail mill scaleup It is the most popular and successful of the powerbased Modelbased procedure for scaleup of wet, overflow ball mills

How can I determine the best RPM and balls to

2023年3月14日 Measure the quantity of solvent (water/non aqueous based) that can be filled in your grinding jar (fill it upto the neck)2020年11月1日 A modified threedimensional quasiwet discrete element method (DEM), which is constructed by adding the drag force and buoyancy and the velocity dependence of the Ballimpact energy analysis of wet tumbling mill using a 2015年10月15日 Learn how to calculate the grinding capacity of your ball mill with 911 Metallurgist This guide provides essential formulas, insights, and tips to optimize your milling process and enhance production efficiencyCalculate Ball Mill Grinding Capacity2003年5月7日 The critical speed of the mill, c, is defined as the speed at which a single ball will just remain against the wall for a full cycle At the top of the cycle =0 andTECHNICAL NOTES 8 GRINDING R P King Mineral Tech2020年8月26日 The document provides information on how to calculate ball mill design and sizing parameters It includes a small ball mill capacity and sizing table, as well as details on ball mill design and power calculations The Ball Mill Design Calculations How To PDF PDF2023年2月11日 Digital Solutions to Evaluate Ball Mill Circuit Recirculating Load and Performance Jeremy Hanhiniemi1,2, Jun Heo2 The database provided by Shi on residence Digital Solutions to Evaluate Ball Mill Circuit

MODULE #5: FUNCTIONAL PERFOMANCE OF BALL

2018年12月9日 equation for ball mill circuits • Define and calculate the classification system efficiency of a ball mill circuit • Define and calculate the grinding efficiency of the ball mill in a 2016年3月21日 To estimate the circulating loads in and the efficiency of each of the two classifiers operating in closed circuit with a ball mill: Original feed may be applied at the ball Common Basic Formulas for Mineral Processing CalculationsCement ball mill process calculation pdf Download as a PDF or view online for free Submit Cement ball mill process calculation pdf Jan 5, 2024 1 like 3,758 views AIenhanced Cement ball mill process calculation pdf PPT SlideShare2013年1月1日 A problem for solving mass balances in mineral processing plants is the calculation of circulating load in closed circuits A family of possible methods to the resolution Circulating load calculation in mineral processing closed Variables in Ball Mill Operation Easy enough to calculate that 12x12x12 will be 1,728 pieces of media If we reduce this to ½” then there will be 24x24x24 or 13,824 pieces of media An 8 fold Variables in Ball Mill Operation Paul O Abbe5 天之前 to ball filling variation in the mill The results obtained from this work show, the ball filling percentage variation is between 12– 37% which is lower than mill ball filling A Method to Determine the Ball Filling, in Miduk Copper

Circulating Load Calculation Formula 911Metallurgist

2015年2月21日 For example your ball mill is in closed circuit with a set of cyclones The grinding mill receives crushed ore feed The pulp densities around your cyclone are sampled and 2023年3月14日 If you follow this PSD you acheive will be +/02micrometer variation from batch to batchif you are using pot mill keep RPM as 80 if u r using high energy ball mill take any How can I determine the best RPM and balls to powder ratio for wet Ball Standard Ball Mill Circuit Arrangement Figure 2 Ball Mill Circuit Productivity vs Circulating Load Ratio (after EW Davis) What is the circulating load ratio in your ball milling circuit? There is a rapid and easy way to calculate it from any set Grinding Bulletin #1 – Metcom TechnologiesBall Mill Loading (wet milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and Ball Mill Loading Wet Milling Paul O AbbeA mill is required to grind 250 tph of limestone from an 80% passing size of 10 mm to 100 μm in a closedcircuit wet overflow discharge ball mill Calculate the mill size required to handle the Mill Charge an overview ScienceDirect Topics2024年3月16日 BallmillCalculationSheet Free download as Excel Spreadsheet (xls), PDF File (pdf), Text File (txt) or read online for free This document summarizes mill calculation Ball Mill Calculation Sheet PDF Scribd

A New Approach to the Calculation of Bond Work Index with

2024年6月29日 Grinding media influence the energy consumption and efficiency of the grinding process during the calculation of the Bond Work index (BWi), a wellknown method for 2021年11月9日 Ball mill is a key equipment for grinding materials thus grinding ball mills are widely used in the mining beneficiation process, and it has a wide range of suitable grinding wet grinding ball mill grinding media calculationHXJQ Dual twostage technological scheme of the drum mill and ball mills Further, the product of separation (coarse) grinded till finish product in long ball mill The plant capacity is 245265 Analysis of the efficiency of the process in closed circuit 2010年9月27日 Fourier transforms are performed according to the frequency component of the signal, which is decided by the window length the mill load (Si, Cao, Zhang, Jia, 2009)(PDF) Modeling of operating parameters for wet ball millball mill circulating load calculation – ball mill,raymond mill,stone ball mill circulating load calculation – ball mill,raymond mill2017年2月13日 Here this Ball Mill Design Calculator Where the finished product does not have to be uniform, The mills can be used either for dry or wet, rod or ball grinding By using a Ball Mills 911Metallurgist

.jpg)

Ballimpact energy analysis of wet tumbling mill using a

2020年11月1日 Wet ballmilling processes using horizontal tumbling mills have been conventionally employed in various industries, eg, mining, ceramics, foods, fine chemicals, Figure 1 Schematic diagram of coneend of a wet system ball mill EXPERIMENTAL WORK To verify the new power draw approach, detailed surveys of the 14 ball mill circuits at 6 different CALCULATION OF THE POWER DRAW OF DRY 2015年10月9日 Calculating a grinding circuit’s circulating loads based on Screen Analysis of its slurries Compared to %Solids or Density based Circulating load equations, a more precise method of determining grinding Ball Mill Circulating Load Formula2006年9月1日 The result of this test is known as the Wet Ball Mill (WBM) value Apparatus The following apparatus is required: ♦ wet ball mill machine, consisting of a watertight steel Chapter 1 – Soils Tex116E, Ball Mill Method for The maximum power draw in ball mill is when ball bed is 3540 % by volume in whole empty mill volume Considering that ball bed has a porosity of 40 %, the actual ball volume is considered Best way to determine the balltopowder ratio in ballmilling?2023年6月15日 They used a typical wet ball mill RTD and classifier sizebysize separation performance to complete the circuit simulator The circuit simulator was input to the circuit feed Full article: The truth about population balance modeling

.jpg)

Ball Mill Design Calculations How to 911Metallurgist

2018年4月8日 Unlock the principles of ball mill design with 911 Metallurgist This guide offers detailed calculations and practical tips to ensure your mill is optimized for performance, 2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating (PDF) Grinding in Ball Mills: Modeling and Process Control2014年3月2日 31 Industrial Ball Mill The ball mill utilized in the sampling survey has an inside diameter of 73 m and length of 96 m and is run in open circuit Under normal operating Effect of Slurry Solids Concentration and Ball Loading on Mill Plan and track work Code Review Manage code changessbm/sbm calculate cost wet ball mill calculate cost 2020年8月26日 The document provides information on how to calculate ball mill design and sizing parameters It includes a small ball mill capacity and sizing table, as well as details on ball mill design and power calculations The Ball Mill Design Calculations How To PDF PDF2023年2月11日 Digital Solutions to Evaluate Ball Mill Circuit Recirculating Load and Performance Jeremy Hanhiniemi1,2, Jun Heo2 The database provided by Shi on residence Digital Solutions to Evaluate Ball Mill Circuit

.jpg)

MODULE #5: FUNCTIONAL PERFOMANCE OF BALL

2018年12月9日 equation for ball mill circuits • Define and calculate the classification system efficiency of a ball mill circuit • Define and calculate the grinding efficiency of the ball mill in a 2016年3月21日 To estimate the circulating loads in and the efficiency of each of the two classifiers operating in closed circuit with a ball mill: Original feed may be applied at the ball Common Basic Formulas for Mineral Processing CalculationsCement ball mill process calculation pdf Download as a PDF or view online for free Submit Cement ball mill process calculation pdf Jan 5, 2024 1 like 3,758 views AIenhanced Cement ball mill process calculation pdf PPT SlideShare2013年1月1日 A problem for solving mass balances in mineral processing plants is the calculation of circulating load in closed circuits A family of possible methods to the resolution Circulating load calculation in mineral processing closed Variables in Ball Mill Operation Easy enough to calculate that 12x12x12 will be 1,728 pieces of media If we reduce this to ½” then there will be 24x24x24 or 13,824 pieces of media An 8 fold Variables in Ball Mill Operation Paul O Abbe5 天之前 to ball filling variation in the mill The results obtained from this work show, the ball filling percentage variation is between 12– 37% which is lower than mill ball filling A Method to Determine the Ball Filling, in Miduk Copper

.jpg)

Circulating Load Calculation Formula 911Metallurgist

2015年2月21日 For example your ball mill is in closed circuit with a set of cyclones The grinding mill receives crushed ore feed The pulp densities around your cyclone are sampled and 2023年3月14日 If you follow this PSD you acheive will be +/02micrometer variation from batch to batchif you are using pot mill keep RPM as 80 if u r using high energy ball mill take any How can I determine the best RPM and balls to powder ratio for wet Ball 2015年6月19日 Ball Mill Power Calculation Example #1 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% Ball Mill Design/Power Calculation 911MetallurgistPilot Plant Design Pilot plant programs provide critical testing and design data Pilot Plant Design2019年8月30日 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting There are many Ball Mill Parameter Selection Calculation JXSC2021年6月24日 The tower mill calculation is based on the ball mill design sheet, but is simplified in that the mill design section is omitted A simple tower mill factor of 70% allows theGrinding Mill Computer Model AusIMM

Digital Solutions to Evaluate Ball Mill Circuit

2023年2月11日 One tool used includes a volumebased residence time ball mill model to constrain simulations and prevent ‘overfilling’ and a loss of grinding performance at high 2001年10月1日 Bond's method (Bond 1952, 1961), which is a powerbased method, is still the principal way for bail mill scaleup It is the most popular and successful of the powerbased Modelbased procedure for scaleup of wet, overflow ball mills 2023年3月14日 Measure the quantity of solvent (water/non aqueous based) that can be filled in your grinding jar (fill it upto the neck)How can I determine the best RPM and balls to 2020年11月1日 A modified threedimensional quasiwet discrete element method (DEM), which is constructed by adding the drag force and buoyancy and the velocity dependence of the Ballimpact energy analysis of wet tumbling mill using a 2015年10月15日 Learn how to calculate the grinding capacity of your ball mill with 911 Metallurgist This guide provides essential formulas, insights, and tips to optimize your milling process and enhance production efficiencyCalculate Ball Mill Grinding Capacity2003年5月7日 The critical speed of the mill, c, is defined as the speed at which a single ball will just remain against the wall for a full cycle At the top of the cycle =0 andTECHNICAL NOTES 8 GRINDING R P King Mineral Tech